our Factory

Our factory is located in Dongguan, Guangdong Province, covering over 3,000㎡ with 3 standardized production lines and advanced equipment. Supported by 100+ skilled workers, we ensure efficient production and strict quality control for premium hardware solutions.

ZX Hardware Factory

Our factory was founded in 2005, starting as a small hardware factory focusing on the production of zinc alloy products. Its core product categories include zinc alloy belt buckles, various zinc alloy accessories and luggage accessories. With solid technological accumulation, it has laid a solid foundation in the industry.

In 2016, as the business scale continued to expand and market demand kept upgrading, the factory separated its production department from the external sales department for independent operation, and officially established CAROSUNG Import and Export Company to connect with market channels through a more professional team. In 2018, to further focus on core development directions, the production tasks of the original zinc alloy-related products were transferred to two sister factories. The company then fully shifted to higher-quality material fields – focusing on the R&D and production of stainless steel luggage accessories and stainless steel jewelry, and gradually expanded to the processing and manufacturing of high-end materials such as titanium alloy and 904 stainless steel.

This transformation mainly stems from the company’s long-term experience in serving the European and American markets: the high-end demand of European and American customers for product materials and process precision has promoted the factory to continuously upgrade its production standards. At present, the company has 80 employees, equipped with professional equipment such as automatic cleaning lines, polishing lines and spot welding machines, and has introduced high-precision processing equipment such as CNC machine tools, forming a complete production line from material processing to finished product processing. This enables it to meet the stringent requirements for product quality in the high-end market and steadily enhance its competitiveness in the international market.

TEL Belt Factory

TEL Belt Factory was founded in 2012 and officially became part of the CAROSUNG Group in 2016, which marked the start of a new stage of large-scale and professional development.

Currently, the factory has a team of over 60 experienced employees, covering professionals in all links from raw material selection, production and processing to quality inspection and packaging. With exquisite craftsmanship and a rigorous attitude, workers ensure that every belt is infused with originality. In addition, the factory is equipped with a series of advanced production equipment, including automatic cutting machines, high-precision sewing equipment and intelligent computer-controlled machines. These devices not only significantly improve production efficiency, but also accurately control the dimensional precision and technical details of products, realizing an effective integration of traditional craftsmanship and modern technology.

Supported by CAROSUNG’s resources, we have always adhered to the core principle of “quality first”. We have established a complete full-process quality management system, ranging from the procurement of high-quality raw materials, intelligent production processes to strict ex-factory inspection. Our products cover various categories such as fashion casual belts and business formal belts, which can not only meet the needs of the mass consumer market, but also undertake custom orders. Looking ahead, we will continue to rely on the dual advantages of talent and equipment, continuously enhance product competitiveness, and bring better products and services to customers.

JT Hardware Factory

Our factory was founded in 2006. Since its establishment, it has been focusing on the R&D and production of zinc alloy products, with core businesses covering zinc alloy luggage accessories, zinc alloy belt buckles and other categories. By virtue of a deep understanding of material properties and stable technological output, it has accumulated a solid reputation in the industry.

In 2017, the factory was officially merged into CAROSUNG Company. With the help of group resource integration, it started a new chapter of standardized and large-scale development. In 2018, based on the adjustment of the group’s business layout, the factory took over the main zinc alloy business from the sister factories under Kaimingsheng Company, further focusing on core areas and becoming an important production base for zinc alloy luggage accessories and belt buckles within the group.

Over the years, the factory has always been committed to the processing technology of zinc alloy materials. Centering on the functional needs and design trends of luggage hardware and belt buckles, it has continuously optimized the production process to ensure the stable performance of products in terms of durability, precision and appearance texture, providing reliable accessory support for downstream customers.

Advanced Facilities, Reliable Capacity

Complete Production Lines

3 automated lines to handle diverse product requirements.

Precision Machinery

Equipped with CNC, polishing, and stamping machines for superior precision.

Experienced Workforce

100+ skilled workers ensuring efficient and reliable delivery.

Strict Quality Control

Comprehensive QC system to guarantee every product meets high standards.

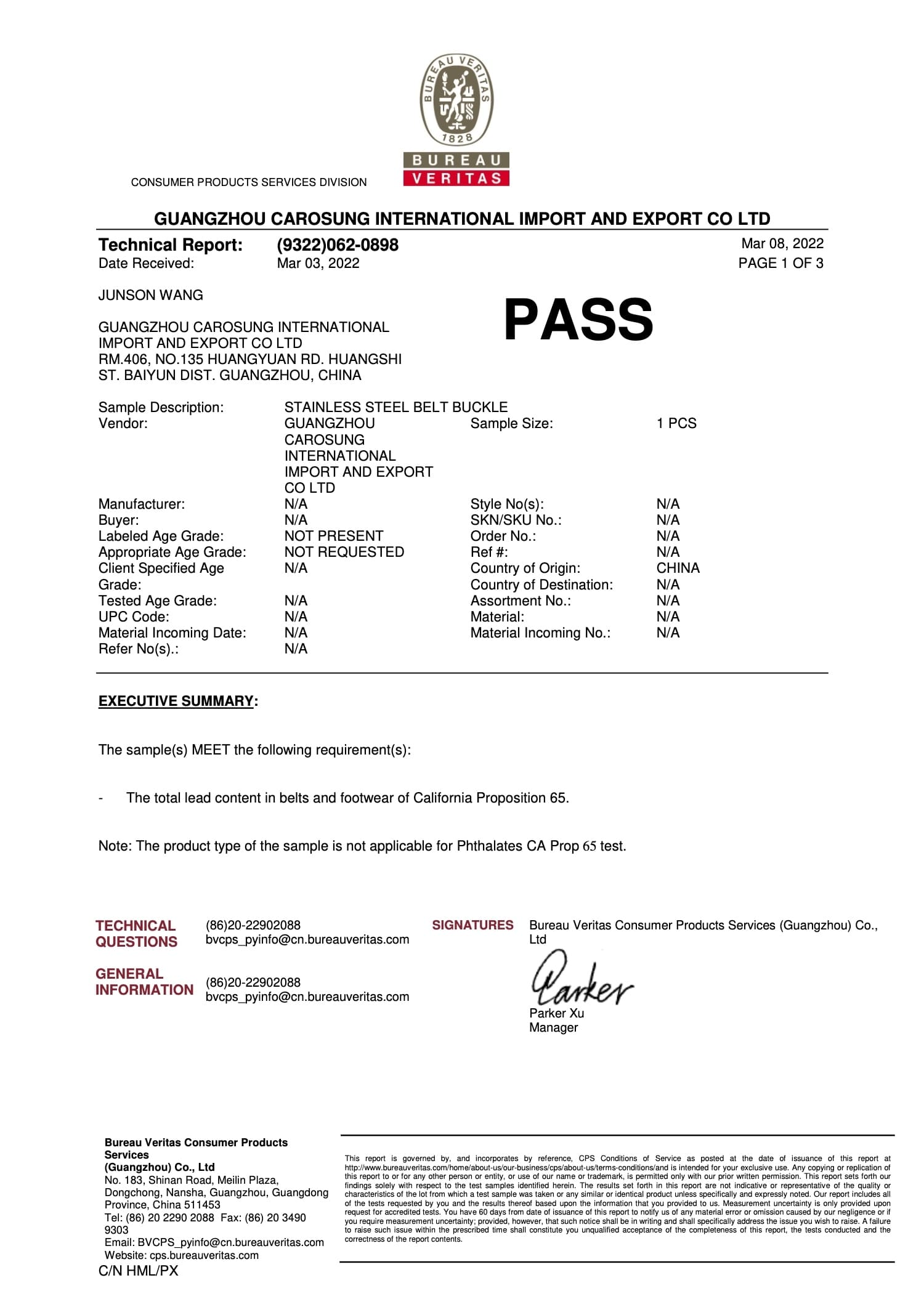

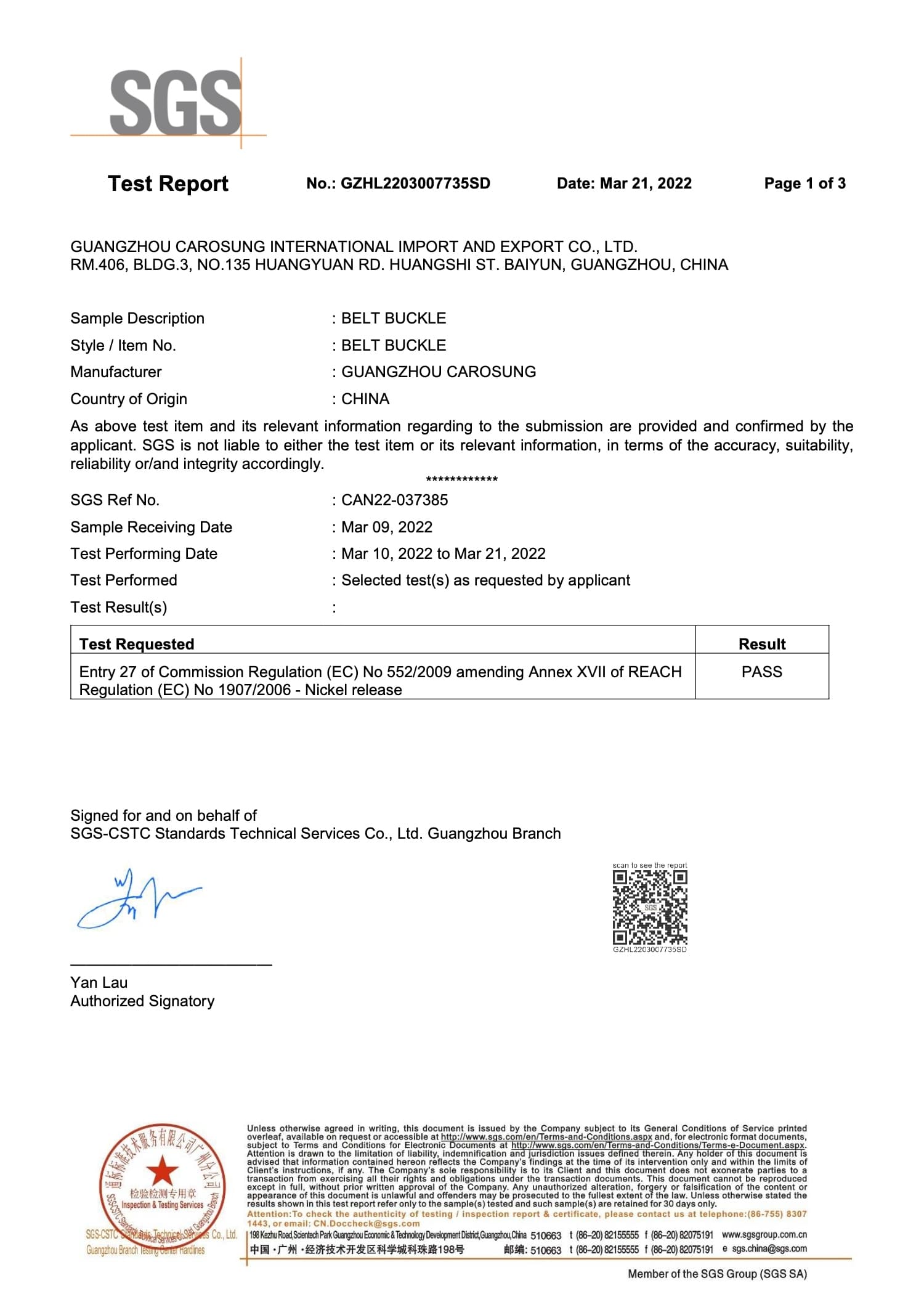

Recognized Quality, Certified Strength